What is Preheat

Preheat, in the context of the lighting industry, refers to the practice of applying a minimal amount of electricity to the filament or fixture of a lamp before fully powering it on. This technique is employed to enhance the lifespan of filament lamps and prevent thermal shock to the filaments. By preheating the lamp, it begins to emit a low-level glow, allowing it to reach the desired brightness more quickly when additional current is applied. As a result, the process of turning on the lights becomes smoother, avoiding the sudden “shock” of activating them from a cold state.

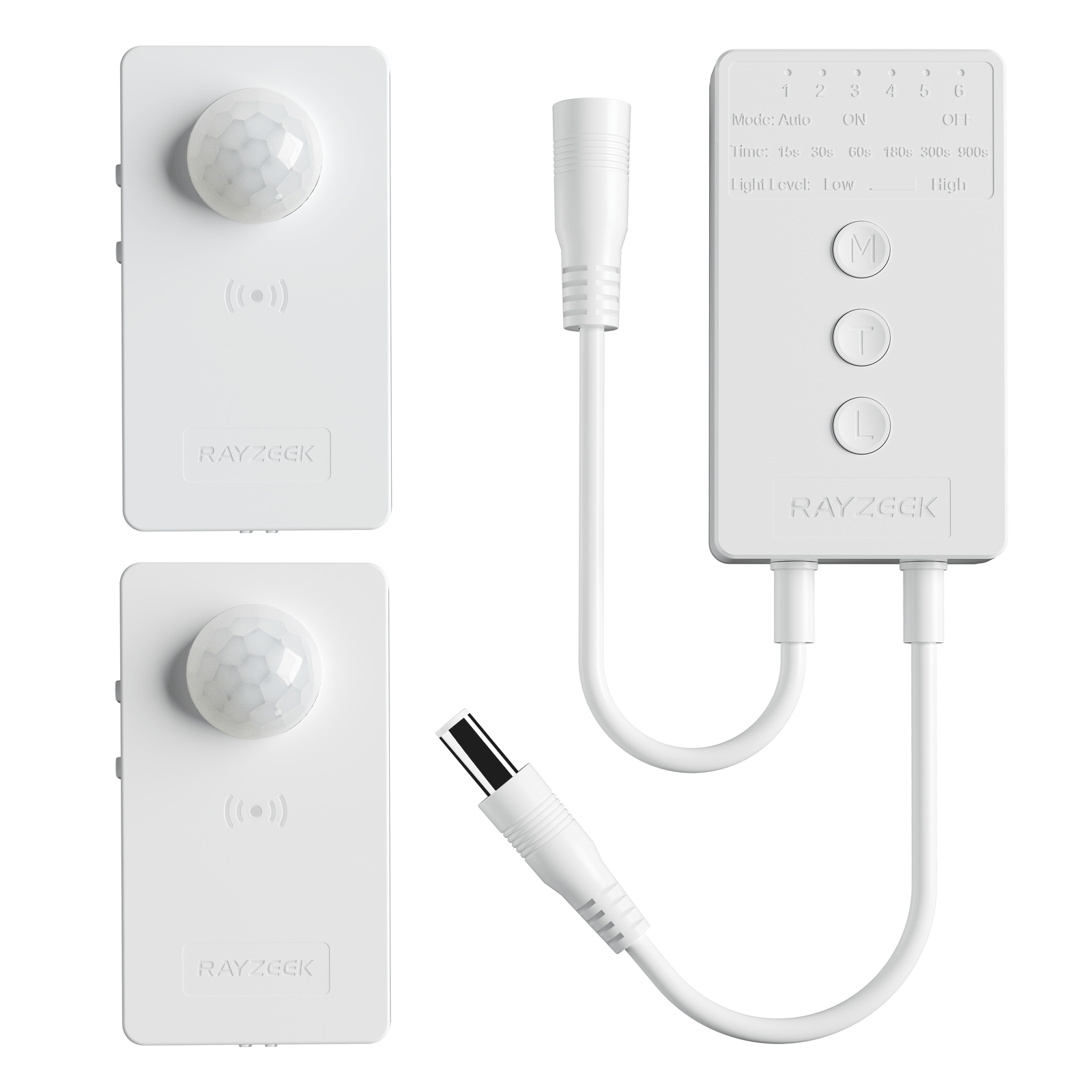

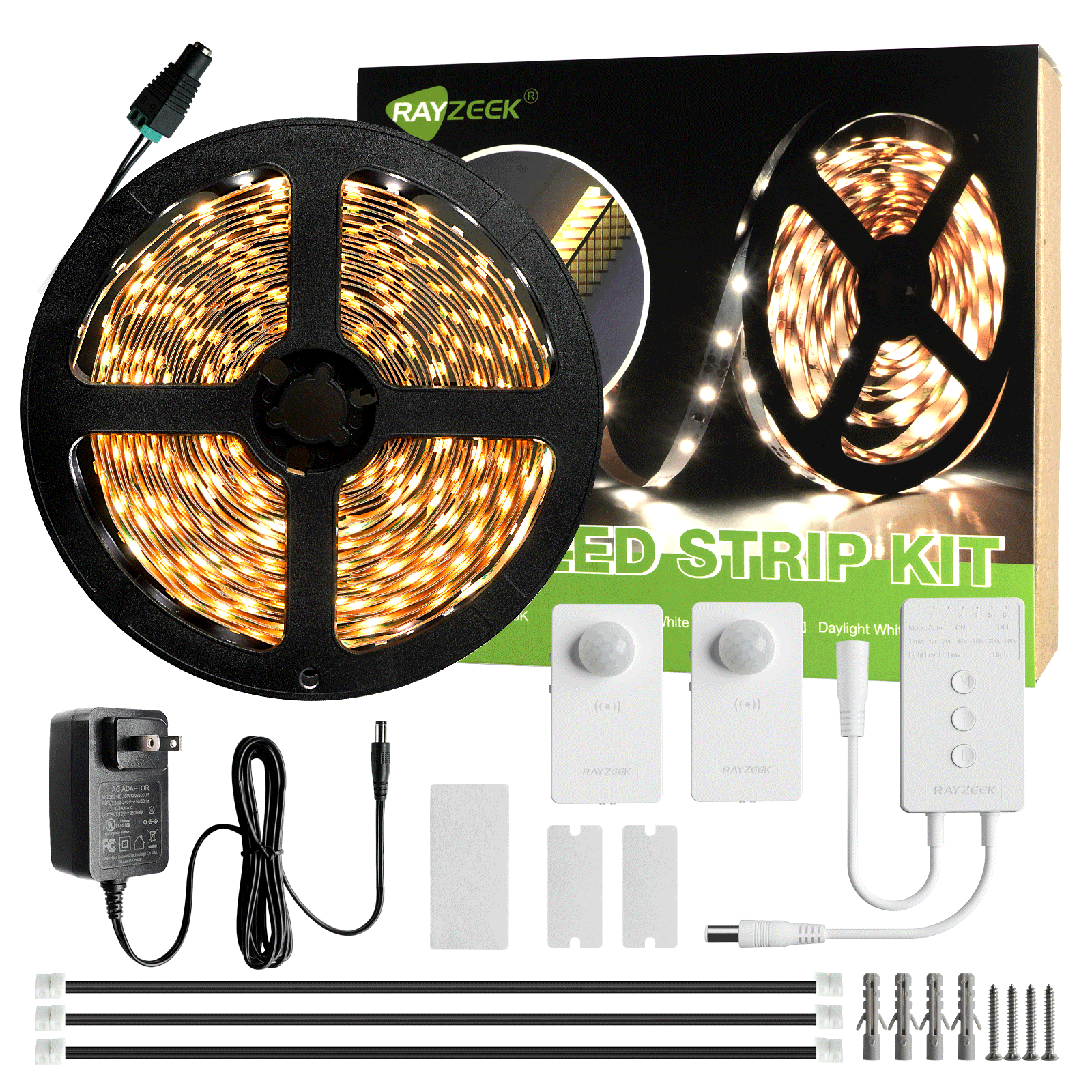

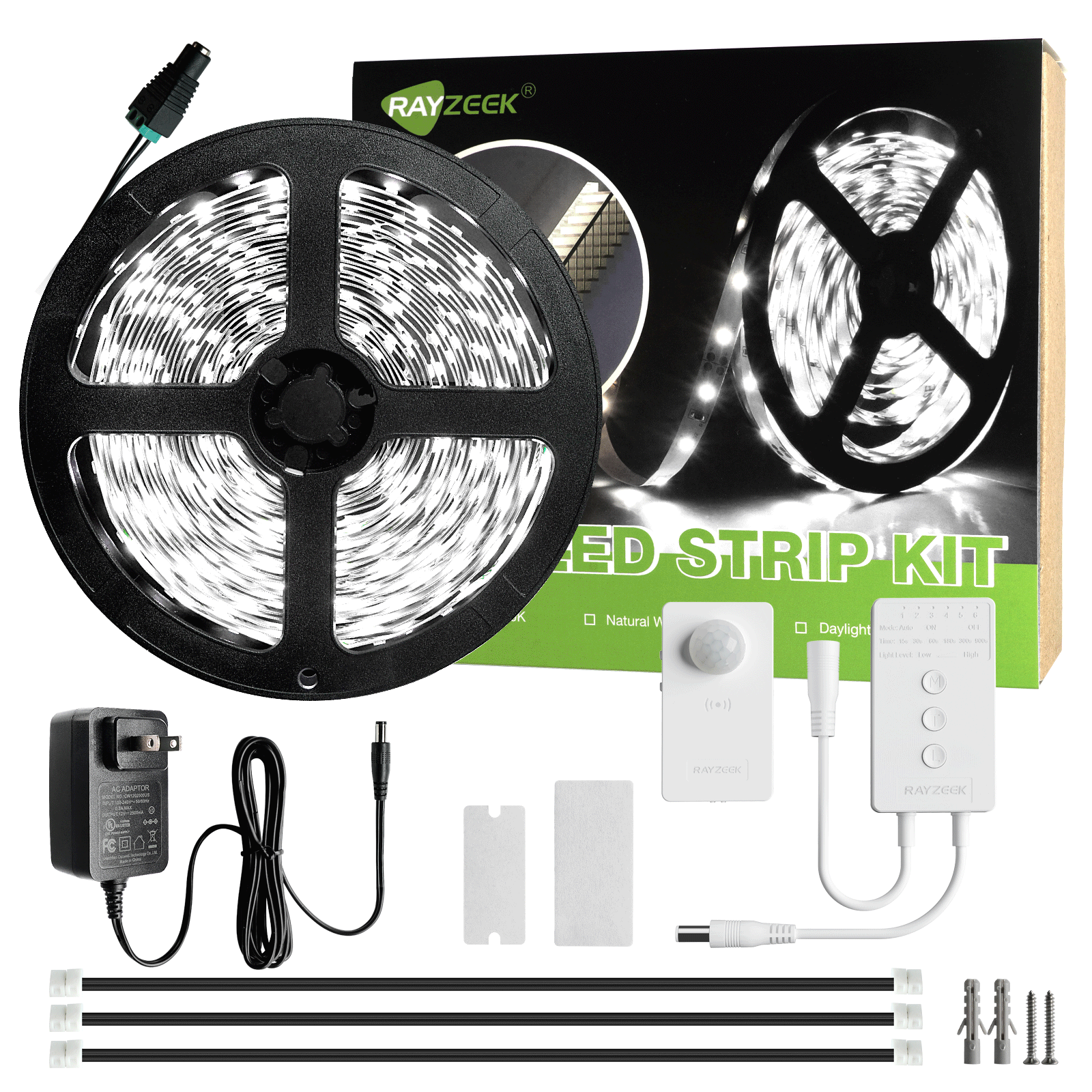

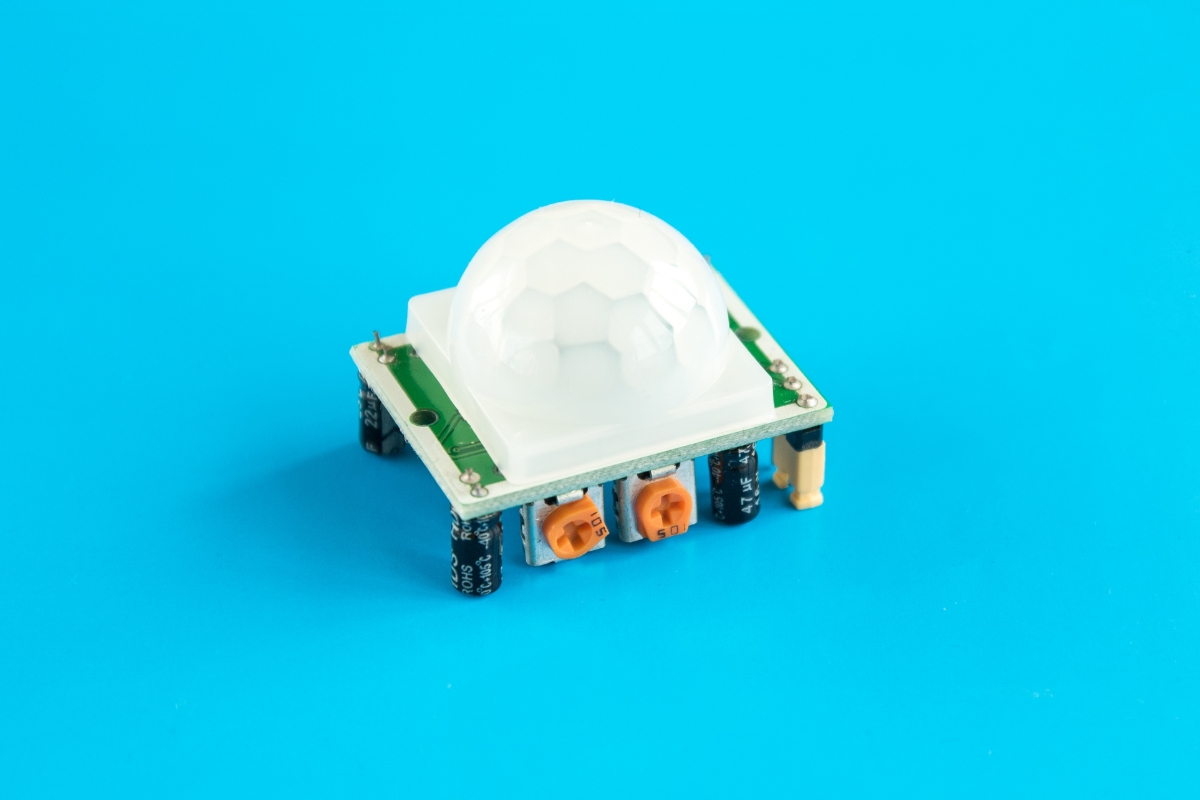

Looking For Motion-Activated Energy-Saving Solutions?

Contact us for complete PIR motion sensors, motion-activated energy-saving products, motion sensor switches, and Occupancy/Vacancy commercial solutions.

Preheating is particularly beneficial for incandescent lamps, especially in colder environments during winter months. By preheating the lamps to a low percentage of power, typically around 3%, before focusing starts, it helps to prevent lamps from blowing due to the cold temperature. This precautionary measure is also applicable to dimmable LEDs, as the internal components of these fixtures require a small amount of current to “wake up” before they can gradually fade up. Preheating with a low-level current aids in achieving a more gradual and seamless transition in the dimming curve of LEDs, preventing them from abruptly turning on.

Moreover, preheating can contribute to the longevity of traditional gels used in lights. By preheating the lights, it helps to extend the lifespan of these gels. Overall, preheating is a technique employed in the lighting industry to increase the lifespan of lamps, prevent thermal shock, and achieve smoother dimming curves. It involves applying a minimal amount of electricity to the filament or fixture before fully powering it on, ensuring a more efficient and reliable lighting experience.