What is Strain Relief

Strain relief refers to a device or mechanism that is utilized to alleviate tension or stress on wires and electrical connections. It is commonly employed in pendant lighting applications, specifically at the point where the wire exits the lamp socket and on the ceiling canopy. The primary purpose of strain relief is to prevent the cable from being inadvertently pulled out of a system, while also controlling the arc of bend and safeguarding against potential cable damage and failure.

Also known as cord grips, strain reliefs play a crucial role in maintaining the integrity and safety of lighting systems. They ensure that the cables remain securely connected and protected from excessive tension or pulling forces. By reducing the strain on the wires, strain reliefs help to prolong the lifespan of the cables and mitigate potential hazards such as electrical shorts or fires.

Maybe You Are Interested In

Strain reliefs come in various forms and designs, depending on the specific application and requirements. They can be made of different materials such as plastic, metal, or rubber, and may incorporate different mechanisms for securing the cable. Common types of strain reliefs include cable glands, cord grips, and strain relief bushings.

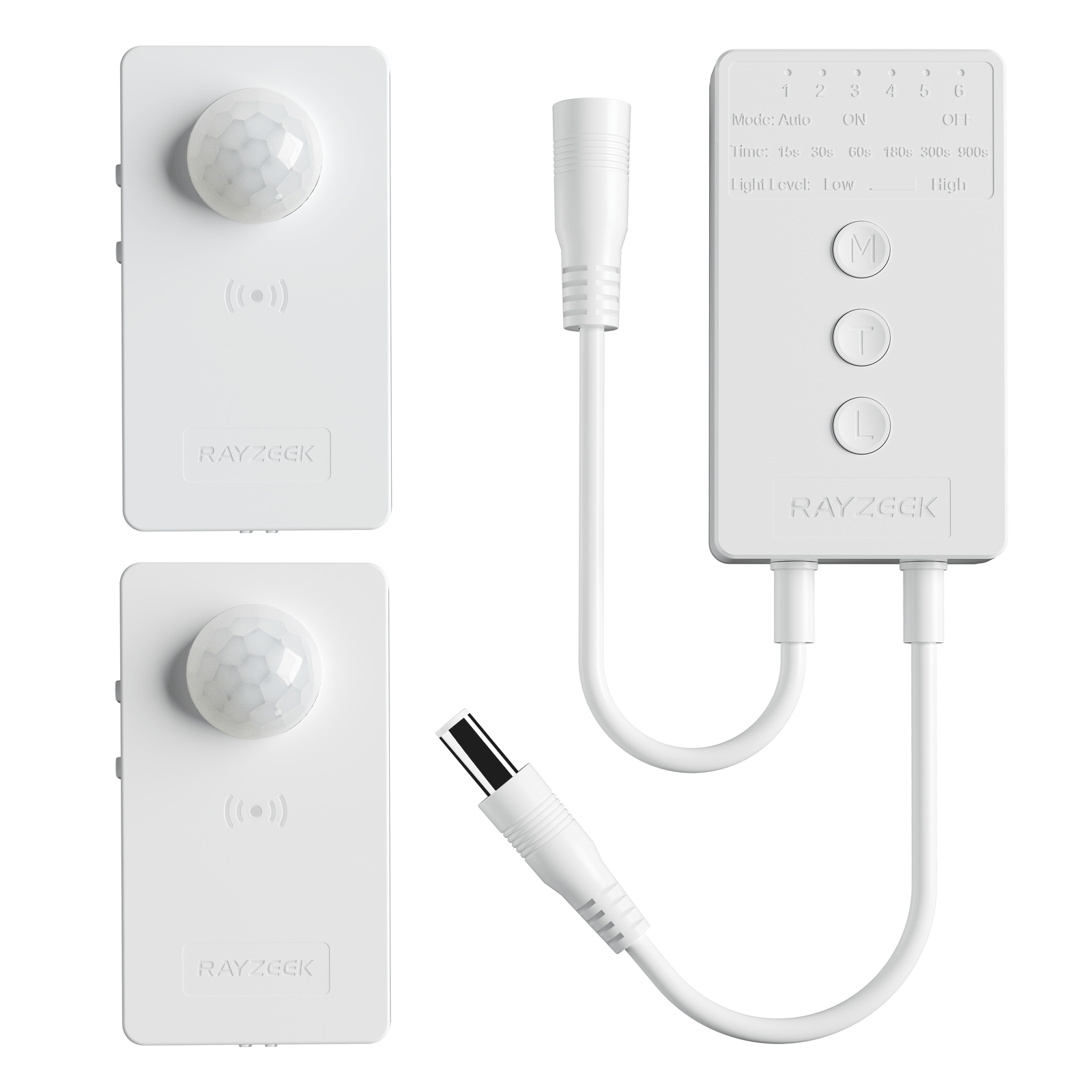

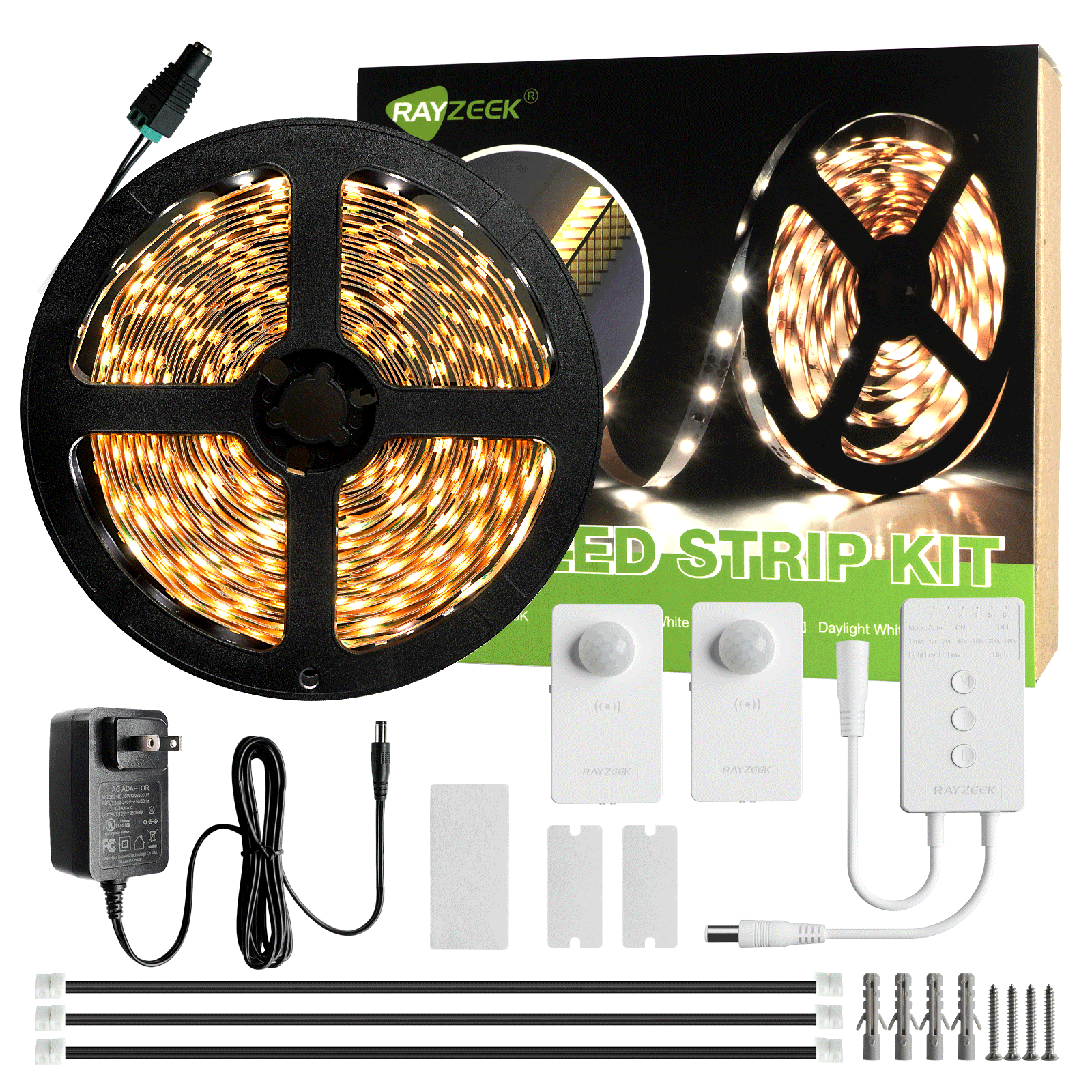

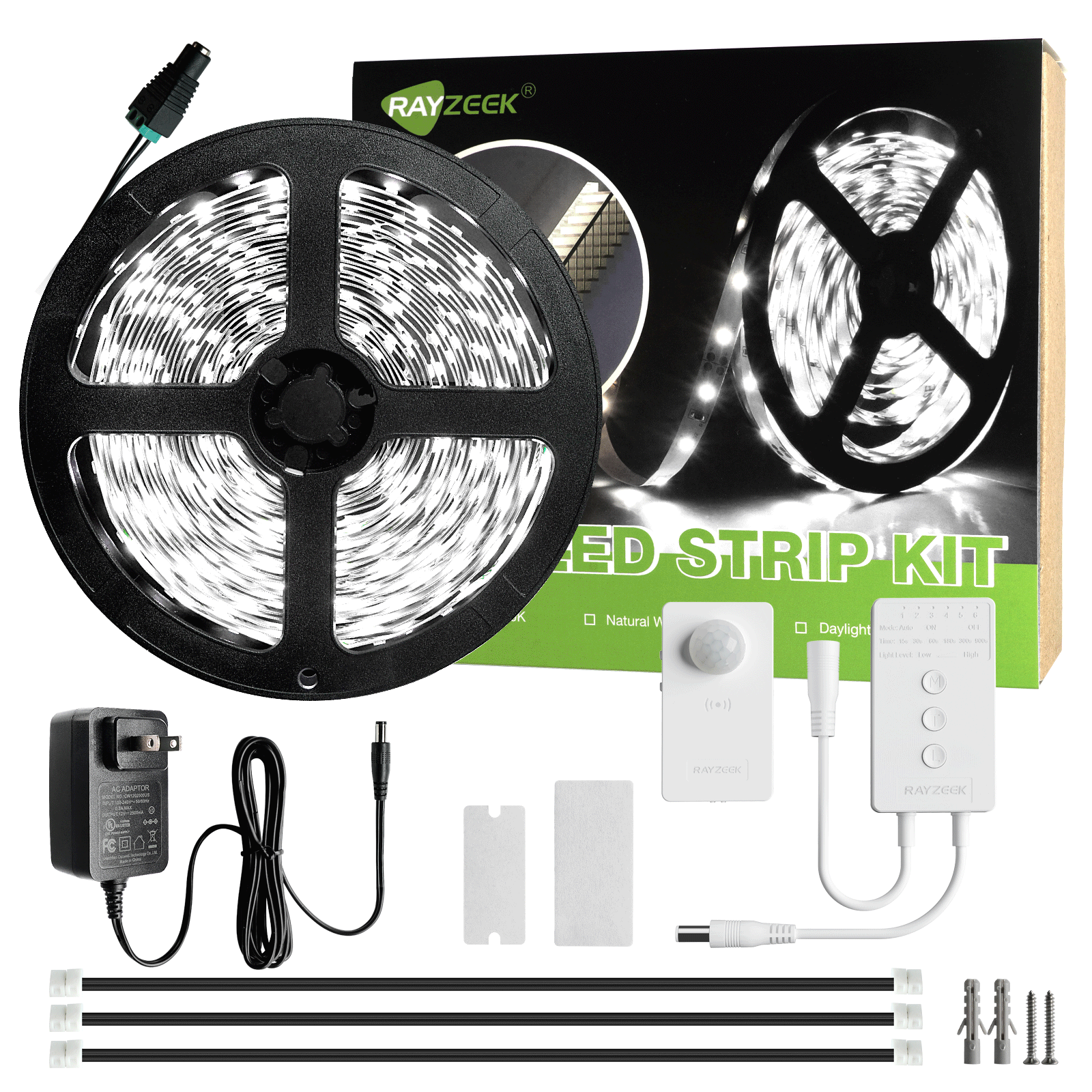

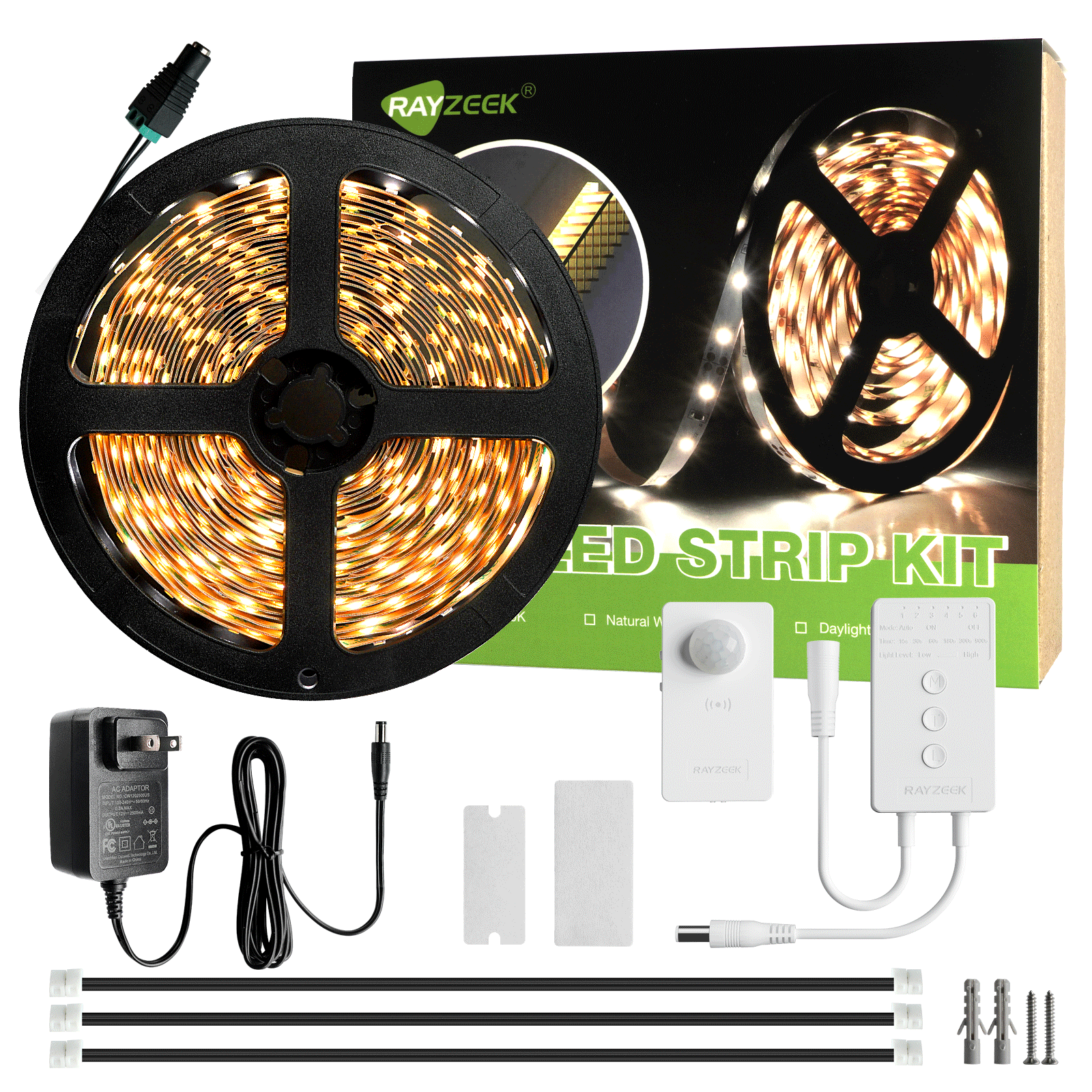

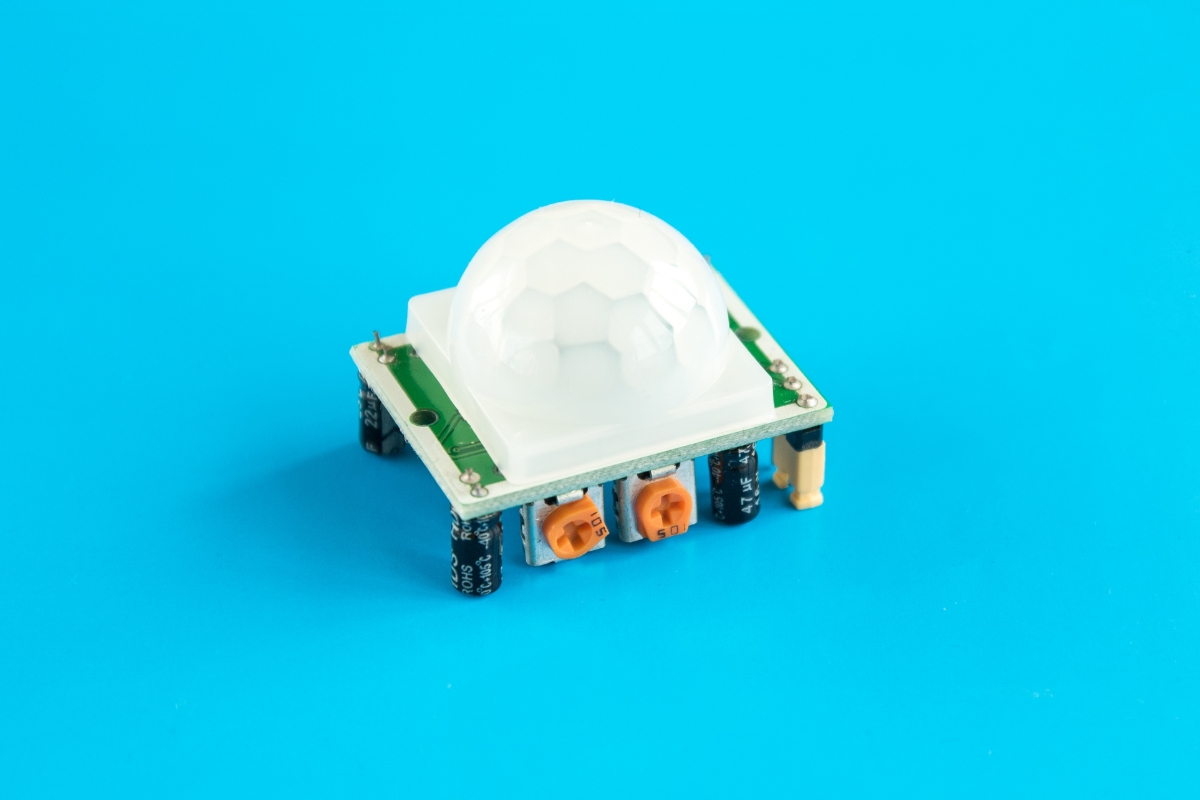

Get Inspired by Rayzeek Motion Sensor Portfolios.

Doesn't find what you want? Don't worry. There are always alternate ways to solve your problems. Maybe one of our portfolios can help.

Frequently Asked Questions

What Is the Purpose of a Strain Relief

A strain relief, also known as a cable gland, serves the purpose of safeguarding the wires and cables by securely fastening the power cord’s cable to the electrical equipment’s panel. Its primary function is to shield the cables from stress and potential damage as they pass through the equipment’s panel.

Is Strain Relief Necessary

Wherever cables are exposed to mechanical strain, such as pulling, bending, or constant movement, it is crucial to have proper strain relief measures in place.

What Are the Different Types of Strain Relief

There are several types of strain relief mechanisms, including cable bushings, cable glands, romex connectors, and wire ties. Cable bushings are designed as hollow liners that surround conductors or cables to ensure electrical isolation. Similarly, cable glands, also referred to as cord grips, serve as another type of strain relief.

What Is the NEC Code for Strain Relief

205.14(2) of the NEC code states that it is necessary to maintain strain relief of cords and cables in order to prevent the transmission of pull to joints or terminals.

How Do You Reduce Strain on Wires

To reduce strain on wires, it is important to maintain a large bend radius for the cable and minimize its diameter. By doing so, you can minimize mechanical stress and prevent issues such as insulation softening caused by higher temperatures and fatigue.